WhatsApp)

WhatsApp)

As the world leader in spiral technology we provide you with unparalleled levels of confidence in the performance of gravity separation circuits. We design, manufacture and supply the MD range of gravity separation equipment including spirals, shaking tables and slurry distribution and laundering systems.

Coal Washing & Handling. Gekko's approach to coal handling and processing stems from a proven understanding that processing of the raw material should be determined by the characteristics of the deposit. Liberation, modularity and coarse gravity separation allow for step change benefits to green and brownfields operations.

Gravity separation is one of the oldest technique in mineral processing but has seen a decline in its use since the introduction of methods like flotation, classification, magnetic separation and leaching. Gravity separation dates back to at least 3000 BC when Egyptians used the technique for separation .

Gravity separation metallurgy has a high processing capacity, low energy consumption, and cost. 8 Gold gravity separation examples. Gravity separation is the most effective method for processing ore and coal such as gold, tungsten, and tin.

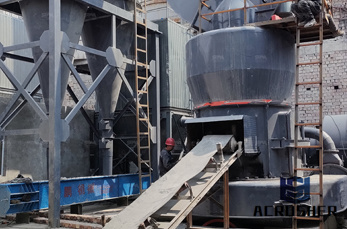

Aug 25, 2016· Explain the rationale behind the layout of coal and mineral gravity separation plant recovery of plant Gravity separation plant equipment, gravity separation plant, high recovery gravity .

Coal gravity separation equipment coal gravity.Separator oal gravity separation equipment.For coal preparation plant coal.Beneficiation plant equipment et price and support online.Denseheavy medium separation hms.Dms processn principle it is the.Simplest of all gravity processes and is a standard.Denseheavy medium separation.

Jul 15, 2019· The main techniques, sieving, gravity separation, electrostatic separation, froth flotation, and oil agglomeration, for separating unburned carbon from fly ash have been discussed in this section. Table 1 shows the advantages and disadvantages of methods for separating unburned carbon from coal .

processes have been the most effective. Dense medium separation (DMS), synonymous with heavy medium separation (HMS), is a form of gravity concentration technology involving float-sink separation that historically has been used predominantly in the coal and diamond processing industries. Many other

Heavy Media Gravity Separation - Mine Engineer.Com. information on gravity heavy media concentration, gravity concentration ... T he SG of separation is the SG of the media slurry, and can range from 1.45 (for coal), ... and is sent back to the magnetic separator circuit for recovery of the media.

Alibaba offers 5,824 coal separator products. About 32% of these are mineral separator, 30% are vibrating screen, and 5% are separation equipment. A wide variety of coal separator options are available to you, such as magnetic separator, gravity separator, and sprial separator.

Sawtooth-wave jig is a kind of energy-saving gravity separation equipment. Due to its sawtooth waveform of the jigging cycle curve, the jig concentrator owns the advantages of even/stable raising water flow and rapid falling water flow, thus it improves the .

Many different kinds of enrichment methods are used in coal preparation, like for example gravity separation processes conducted in heavy dense media, in jigs or on shaking tables or physico-chemicals processes like flotation process. One of the methods used in coal beneficiation process is dry method.

What Is Coal Preparation? • Coal preparation is the removal of undesirable material from the Run-of-Mine (ROM) coal by employing separation processes which are able to differentiate between the physical and surface properties of the coal and the impurities. Through coal preparation, a uniform product is achieved.

H-CSS Series Teetered Bed Separator. 1.Int roduction of TBS. The teetered bed slurry separator is mainly composed of material feeding and spreading device, disturbing separating room, upwardflow injection system, cleaned coal flow guiding system, density detecti on device, gangue discharging gate control system and so on.. 2.Features of TBS. 2.1.

Alibaba offers 5,355 coal spirals products. About 10% of these are conveyors, 8% are mining machinery parts, and 7% are steel pipes. A wide variety of coal spirals options are available to you, such as sprial separator, gravity separator, and magnetic separator.

The new product Three Products Separator (TPS) is the equipment based on ordinary TBS and using two stage separation to realize more efficient coarse coal slurry separation. It makes the result of coarse coal slurry separation more precise, especially when the coal quality is poor TPS has incomparable superiority than traditional TBS.

May 20, 2016· Gravity Separation Jig Wholesale, Gravity Separation Suppliers . coal mining equipment, gravity jig separation machine .. Diesel engine 30tph tin beneficiation plant processing flow chart 2017 separating equipment for gold. Chat With Sales. gravity separation for .

Research of Fully Mechanized Mining Technology of Ultra thin Coal Seam and It s Application; HOT Resolved A World's Problem about the Low Coal Seam Mining Technology Application of Electrical Haulage In-web Shearer on Working Face of Ultra-thin Coal Seam with Large ; The Introduction of Placer Gold Ore Dressing Technology and Equipment

The Gravity Separator makes a highly sensitive dry separation on the basis of one of three particle characteristics: density, size or shape. When size and shape are controlled within certain limits, the gravity separator is unmatched in its ability to separate a complex mixture by density.

Many different kinds of enrichment methods are used in coal preparation, like for example gravity separation processes conducted in heavy dense media, in jigs or on shaking tables or physico-chemicals processes like flotation process. One of the methods used in coal beneficiation process is dry method.

how to separate coal and sand equipment; ... Coal gravity separation equipment, coal gravity separator. Mining & Construction Equipment Manufacturer & Building Solutions Together.Very early media separation used sand mixtures and water to separate coal from rocks such as shale and sandstone, however the sand was very difficult to recover and ...

A coal preparation plant (CPP; also known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or wash plant) is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or ships.

Coal preparation, or beneficiation, is a series of operations that remove mineral matter (i.e., ash) from coal.Preparation relies on different mechanical operations (not discussed in detail here) to perform the separation, such as size reduction, size classification, cleaning, dewatering and drying, waste disposal, and pollution control.

for the separation of fine materials. For fine coal in gravity field, minor particle size leads to lower settling velocity difference between particles with different densities. Traditional gravity separating equipment, such as dense-medium cyclone and hindered bed separator, cannot achieve effective separation

WhatsApp)

WhatsApp)