WhatsApp)

WhatsApp)

Asphalt milling or asphalt grinding is performed by heavy-duty pieces of construction equipment known as a milling machine or a cold planer. Within milling machines, there is a large rotating drum that removes and grinds the surface of the asphalt. Click to view our line of Roadtec Cold Planers.

Oct 04, 2014· Electric plate mills have an output of approximately 67 kg per kW per hour. Thus, a plate mill equipped with a 4 kW electric motor may process approximately 270 kg of grain per hour. In parts of West Africa (e.g. Nigeria) and Central America, plate mills are used for the wet grinding .

Whether you are looking for a flour mill, sorghum press, or flaking mill, we have the highest quality, made in the USA, mills in the world. Quality from our family to yours. GrainMaker | Made in Montana Grain and Flour Mills – The Finest Engineered and Crafted Mill .

Asphalt milling or asphalt grinding is performed by heavy-duty pieces of construction equipment known as a milling machine or a cold planer. Within milling machines, there is a large rotating drum that .

For sundries like iron block in materials, when they move to the fringe of grinding plate, because of their heavier weight, they would drop to the lower cavity of grinding mill and next be sent into the discharging port by scarper installed at the bottom of grinding plate and finally be discharged out of the grinding mill.

In its base configuration, the mill comes equipped as a disc mill (aka disk mill) with 10.5" diameter high carbon steel grinding plates. The plates turn at 2,800 rpm's. The plate burrs can be replaced with optional stone burrs for extremely fine grinding .

Jan 07, 2015· Raw mills usually operate at 72-74% critical speed and cement mills at 74-76%. 3.2 Calculation of the Critical Mill Speed: G: weight of a grinding ball in kg. w: Angular velocity of the mill tube in radial/second. w = 2*3.14*(n/60) Di: inside mill diameter in meter (effective mill .

The Rotor Beater Mill SR 300 is suitable for coarse and fine size reduction, either in batches or continuously. It can process dry, soft, medium-hard, organic and inorganic substances. With its adjustable speed of 3,000 to 10,000 rpm the rotor beater mill .

grinding mill lower weight manufacturer - trivenischoolcoin lower breakage super harder grinding media balls, Grinding Mill Lower Weight Plate Manufacturer Amazon: YumyKit Electric Meat Grinder Food, Plan term and select coverage begins date of purchase and is inclusive of the manufacturer's, with Grinding Plates, 1 x Lower Blade 1 x

Diameter – depending on the material, ranging from 0.05 mm to 2 mm for small media mills, up to 1/8" to 1" for traditional Attritors and up to ½" to 2" for ball mills Composition – metallic grinding media like carbon steel, forged steel, stainless steel or chrome steel grinding .

Ryerson is a leader among North American metal suppliers in the carbon steel bar market. We offer carbon steel bar in a variety of shapes, including flat, round, half round, hexagon and square. Carbon .

WonderMill makes a line of affordable and competitive manually-operated and electric grain mills, including the acclaimed WonderMill and its successors, the Junior Hand Mill series. WonderMill grain grinders have uses ranging from grinding wheat flour for baking to making homemade granola and cereal, to even grinding .

Since the weight of pebbles per unit volume is 35–55% of that of steel balls, and as the power input is directly proportional to the volume weight of the grinding medium, the power input and capacity of pebble mills are correspondingly lower. Thus, in a given grinding circuit, for a certain feed rate, a pebble mill .

There are basically two groups of Grinding Mill Liners. Ones with a HIGH PROFILE and those with a LOW PROFILE. The high profile liner is designed to give the media the higher lift. This type will be used in mills that are designed for primary grinding and as a result require the impact of the higher cascade. Ball mills working as the secondary portion of a grinding circuit will utilize the ...

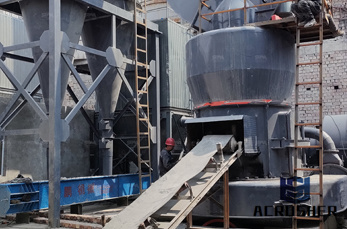

The grinding plate rotates under the action of main motor of LM Vertical Grinding Mill and the reducer. Meanwhile, hot wind enters the vertical mill. After raw materials fall onto the center of grinding plate, they move to the edge of grinding plate .

Burr mills - The most common type of new and used grain mill for sale on eBay, these operate using a pair of grinding plates, one fixed and the other powered to rotate. Whole grains are fed through a hole between the burrs to be milled one of two ways.

The H&S GM170 offers the convenience, dependability and smoothness of hydraulically operated feed making on your farm. The PTO driven 21″ grinder mill features an eight "A" section banded V-belt for a positive drive and a quick release pin to disengage the mill.

Liner plates grinding mill - Manufacturer Of High-end ... Liner plate in cement mill laurastownshiptoursco. The lifetime of different parts ponents of mill liners also varies due to the wear of the parts, for technical The lifter bars are 210 mm wide and 350 mm high the shell plates between the liners protect the mill shell and developed a mathematical model for the replacement of mill liners ...

Plate, Sheet, Bar, Tube & Structural Products. Penn Stainless Products is your premium supplier and processor of specialty stainless steel, high-temperature stainless grades, corrosion resistant stainless grades and duplex materials — in multiple product forms, including stainless steel sheet, plate.

Feb 10, 2013· E. Special case: the bicycle-mounted mill and the pedalling grinder These mills have been developed by the TDRI, Tropical Development Research Institute, England. These two devices (see image 23) are both very similar. In the first case, the mill .

With the assistance of latest technologies, our experts have successfully designed Grinding Mill. There are varieties of Grinding Mill available like: Jigger, Shoe link, Leg Bearing, Driving Pulley, Grinding Plate and others. Procuring the material from trustworthy vendors, the outcomes are ready to

All Grinding Mill & Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways. The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drum.

Every mining operation has a unique grinding process. has experience of over 8,000 grinding mills globally, including manufacturing and delivering the largest SAG/AG mills in the world. Our experts welcome the opportunity to assist you with circuit and circuit control design as well as start-up, operation, and optimization of your mill.

Lumsden ground steel plate suppliers, delivering to the whole of the UK. West Yorkshire Steel supply ground steel plate in a wide variety of steel specifications. Lumsden ground steel plate is suited for applications which require a tighter tolerance than commercial hot rolled or sawn plate.

WhatsApp)

WhatsApp)