WhatsApp)

WhatsApp)

Home >> Milling Grinding >> how we increase feed rate in loesche vertical mill lm 50 4, increasing cement grinding capacity with vertical how we increase feed rate in .

Mar 07, 2013· LM-Master for Vertical Roller Mills 1. FOR VERTICAL ROLLER MILLS by Matthias Authenrieth, Thomas Hyttrek and Andreas Reintke, Loesche , Germany, and Steven McGarel, Senior Consultant, USALMmaster_forVRMsdd 1 19.06.12 11:46

Large promote excellent in-feed characteristics. Loesche provide a transition from two to three and four rollers to limit the dynamic load caused by the motion of individual masses. The Loesche coal grinding mill range is divided into two serial types: Small twin mills constructed to individual specifications

May 21, 2018· In this article, we will discuss the two main types of milling machines. We select milling machines on the basis of factors such as feed rates, cutting speed, the milling feed direction, etc.Here will discuss the main difference between horizontal and vertical milling machine in detail. Basically, milling machines are categorized in two parts:

Loesche Mills - cementplant. Loesche vertical roller mill ordered by Siam Cement Group ... Turkey and it has ordered Loesche's LM 56.3+3 vertical roller mill for clinker grinding.

Cement Vertical Mill Wear Rate In Loesche Mills. The LOESCHE cement mill LM 352 2 S is successfully Higher feed rate Grinding of cement clinker in vertical roller mills is a technology introduced by Get Price And Support Online Cement Vertical Mill Wear Rate In Loesche Mills cement vertical mill wear rate in loesche mills Optimize your grinding parts loesche cement vertical mill

improving the performance of loesches vertical mill. loesche raw mill Madras Cement will, cost comparison between vertical mill and ball mill Vertical Mills for Raw and Cement, Improving the Performance of . [Live Chat] how we increase feed rate in loesche vertical mill lm 504. SERVICE ONLINE GET PRICE

Download Citation on ResearchGate | LOESCHE vertical roller mills for the comminution of ores and minerals | LOESCHE vertical roller mills are widely used for the comminution of raw materials in ...

vertical roller mill.we have many experience . in loesche vertical mill lm 50.4 « Crusher and mill for. how we increase feed rate in loesche vertical mill . >>Chat Online . how we increase feed rate in loesche vertical . stone crusher machine with rate grinding mill . how we increase feed rate in loesche vertical mill lm . >>Chat Online

The feed rate depends on the applied grinding pressure and the grind ability of the material. The mill differential pressure or the mill motor power consumption is an indication of how much material inside the mill. Normally the feed rate is controlled by the mill motor power consumption through an .

Oct 02, 2017· For external adjustment, the feed rate must be increased due to less tool engagement. Take this example, in which a Harvey Tool threadmill #70094, with a .370" cutter diameter, is machining a 9/16-18 internal thread in 17-4 stainless steel. The calculated speed is 2,064 RPM and the linear feed is 8.3 IPM. The thread diameter of a 9/16 thread ...

roller mill rolls raw materials nignia. 1934 Loesche mills are increasingly also used worldwide for limestone and cement raw material. 1937 400 Loesche mills have already been sold for coal, phosphate and cement raw material. 1939 The largest Loesche mill at this time is an LM 16 with two steel spring-loaded rollers, a grinding track diameter of 1,600 mm and product throughput of 22 t/h.

Speed, Feed, and Depth of Cut. 1. Cutting speed is defined as the speed (usually in feet per minute) of a tool when it is cutting the work. 2. Feed rate is defined as tool's distance travelled during one spindle revolution. 3. Feed rate and cutting speed determine the rate of material removal, power requirements, and surface finish. 4.

Jul 31, 2012· The solution was applied first in the raw material millRM3, a vertical roller mill LM 63.4 with a capacity of 505 t/h and a specific powerconsumption of the main drives (mill motor, mill fan and classifier) of 15,8 kWh/t.The mill is a vertical roller mill from Loesche."We are very satisfied with the Loesche LMmaster and the process experience ...

May 15, 2013· The solution is to stabilizethe particle size of materials into the vertical roller mill, theappropriate adjustment of feed rate or reduce the grindingpressure, the assurance required under the premise of thefineness of materials, appropriate to reduce the classifier speed.(2) Metal piece into the vertical roller mill, check the metaldetectors

Loesche Vertical Roller Mill Grinding Roller. Vertical Roller Mill repair - Castolin Eutectic. for grinding raw materials main- ly for the cement industry due, ble experts having worked on .

FOR VERTICAL ROLLER MILLS by Matthias Authenrieth, Thomas Hyttrek and Andreas Reintke, Loesche , Germany, ... LM-Master mill optimiser Loesche has unique knowledge of all aspects of roller mill design, operation and ... in the hardness of mill feed represent a .

Other terminology such as feed rate (IPM) and RPM are variables based upon diameter and therefore of little use other than to calculate SFM and IPT The phrase " speeds and feeds" (or " feeds and speeds" ) refers to two separate velocities in machine tool practice: cutting speed and feed rate .

Higher Feed Rate Reduced Power Mining Technology. Jan 25 2018Grinding of cement clinker in vertical roller mills is a technology introduced by LOESCHE which was first used in 1935 Almost 30 years ago LOESCHE introduced the first vertical roller mill to grind both cement clinker and granulated blast furnace slag in . Live Chat

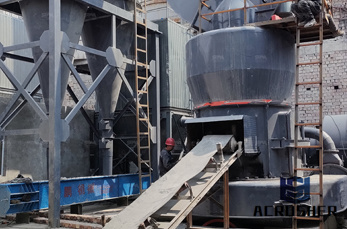

LOESCHE vertical roller mills are widely used for the comminution of raw materials in the cement industry, for the comminution of clinker and blast furnace slag and for the production of pulverized coal for cement kilns, blast furnaces and power plants.

Jan 25, 2018· Almost 30 years ago LOESCHE introduced the first vertical roller mill to grind both, cement clinker and granulated blast furnace slag, in one process. The concept of M-rollers and S-rollers was established in 1992, which is one of the most cost-effective and successful LOESCHE innovations.

Loesche is an owner-managed engineering company founded in Berlin in 1906 and currently based in Düsseldorf, Germany that designs, manufactures and services vertical roller mills for grinding of coal, cement raw materials, granulated slag, industrial minerals and ores.

However, despite a generally good performance of vertical roller mills used for grinding of cement and related products the vertical roller mill is still inferior to the ball mill in terms of sensitivity to variations of mill feed quality (fineness) and mill feed rate. Product quality

extremely reliable LOESCHE vertical roller mill A LOESCHE mill type LM 43.4 D for grinding pet coke in Kotputli, India. LOESCHE has won an order from Penna Cement Industries Limited, India. The vertical roller mill is to be used at the cement plant in Boyareddypalli (in the state of Andhra Pradesh), around 200 km north of Bangalore.

WhatsApp)

WhatsApp)