WhatsApp)

WhatsApp)

Three highly researched 3D metal powder production ... Oct 26, 2016 ... Milling is a process of converting a metal to a powder by mechanical methods like grinding crushing or pulverizing. This is one of the most... Get Quote; Economic Considerations for Powder Metallurgy Structural Parts

Milling is an important process of manufacturing technology and basically it refers to the removal of metal from the work piece using a tool which has several cutting points and is rotating about its axis. Thus each cutting point removes a little bit of the metal but since there are multiple such points and the tool is rotating at a fast speed, the overall removal is quite brisk. You might be ...

process grinds the powder materials by impact/collision & attrition. • Milling can be dry milling or wet milling. In dry milling, about 25 vol% of powder is added along with about 1 wt% of a lubricant such as stearic or oleic acid. For wet milling, 30-40 vol% of powder with 1 wt% of dispersing agent such as water, alcohol or hexane is employed.

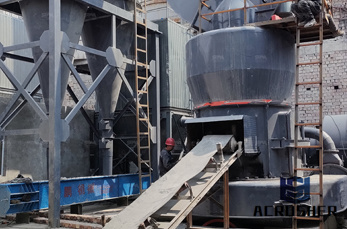

Inicio>Solución-> milling of metal powder process . La planta de trituracion de arena 700-1500 tph.

Powder metallurgy (PM) is a term covering a wide range of ways in which materials or components are made from metal powders. PM processes can avoid, or greatly reduce, the need to use metal removal processes, thereby drastically reducing yield losses in manufacture and often resulting in lower costs.

A milling method (P-milling) combining mechanical milling and dielectric barrier discharge plasma were established by them.They reported that the metal powder prepared by P-milling had a lump-like morphology with very high specific surface area. The lump- like powders were agglomerate of fine primitive particles.

Milling Of Metal Powder Process Additionally, the process integration of the mill must be designed according to the performance of the mill : Open loop or closed loop milling can be implemented. In open loop milling, the feed will go through the mill only one time, it is . Jaw Crusher.

Metallic powders are also commonly used in nuclear power plants, as metallic powders are turned into pellets that are put into uranium rods. Whether it is in a car or a power plant, metallic powders are used in many different manufacturing processes, and Hosokawa has the application to process them.

Metal Injection Molding (MIM) is a variation on traditional plastic injection molding that enables the fabrication of solid metal parts utilizing injection molding technology. In this process, the raw material, referred to as the feedstock, is a powder mixture of metal and polymer.

Sep 25, 2016· On this channel you can get education and knowledge for general issues and topics.

Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. The milling process requires a milling machine, workpiece, fixture, and cutter. The workpiece is a piece of pre-shaped material that is secured to the fixture, which itself is attached ...

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a work piece. This may be done varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations.

Conversioneering® works equally well on new product development or reducing costs of existing components. The MPP team, consisting of experienced Metallurgists, Tool Designers, Process Engineers, and Quality experts, has developed this proven process for engineering precision components using powder metallurgy (pm) or Metal Injection Molding ...

What is ? is a free online handbook giving explanations, design methods and operational tips on the most common unit operations and equipment found in Industries processing powders. It gives materials for Engineers who, around the world, have to design, operate or troubleshoot a powder handling process.

Powder Processing & Technology, LLC provides the equipment, facility and manpower for complete powder toll processing including wet grinding, toll milling and toll classification. We have the ability to pelletize powders, mill down pellets to powders, mill powders down to 0.5 µm in size, and batch and blend various sized powder quantities.

Manufacturing Metal Powders. Metals are first reduced to individual particles through methods including atomization, chemical precipitation, commination and hydrogen reduction. Atomization is the process used commercially to produce the largest tonnage of metal powders.

Powder milling process, using ball or rod mills, aim to produce a high-quality end-product that can be composites and nanocomposites, and nanocrystalline powder particles of intermetallic compounds, amorphous, hydrides, nitrides, silicates, etc. Powder milling process has been continuously improving by introducing numerous innovative types of ...

Alibaba offers 68,552 metal powder milling products. About 87% of these are machining, 1% are milling cutter. A wide variety of metal powder milling options are available to you, such as broaching, drilling, and milling.

In the special case of cemented carbide materials, mixing is carried out in a ball mill, in order to coat the individual carbide particles with the binder metal (e.g. cobalt). As the very fine powder particles involved have poor flow characteristics, the mixture is subsequently granulated to form agglomerates.

Powder Milling. Powder milling is a vital part of solids processing in the pharmaceutical, food, chemical and allied industries. The Hanningfield Uni-Mill conical screen mill is perfect powder milling and can be use for both the dry and wet milling of material, the de-agglomeration of raw material and the reclaim of powder from discarded ...

milling of metal powder process Process for dry milling of aluminium flakes – milling of metal powder process. production process of dry milling aluminium powder. Ball Mill Metal Flakes. dry ball milling process of aluminum flake powder « mine .

Water atomised powders are therefore the material of choice where high green density is sought in PM structural parts. Non-ferrous metal powder production Inert gas atomisation. Non-ferrous metal powders are produced by a variety of means. The most significant of these is another atomising process, this time using an inert gas as the atomising ...

Nov 24, 2017· Introduction to Milling Operation, classification of milling process, powder metallurgy, basic steps in power metallurgy process. All the best, Mech Zone htt...

ball mill metal powder grinding - tcfuwhrorg. 2018-11-08· High energy ball milling process for nanomaterial synthesis It is a ball milling process where a powder mixture placed in the ball mill is The synthesis of nanostructured metal oxides for gas detection is one of the most. ball mill metal powder wet ball mill - picoproductionscoza

WhatsApp)

WhatsApp)