WhatsApp)

WhatsApp)

Vertical Screen Scroll. HVC Vibratory Centrifuge. VC Vertical Vibratory Centrifuge. HSC Horizontal Scroll. CMI™ Horizontal Screen Scroll Centrifuge. Overview. Features. Resources. The HSC Horizontal Screen Scroll Centrifuge is designed to be user-friendly while lowering the cost of installation, operation, maintenance and repair. ...

1. Introduction. Coal accounts for 30% of the world's energy resources and supplied more than 60% of China's total energy consumed in 2015,, .Coal preparation is the most economical and effective way to reduce coal-burning air pollution for efficient and clean utilization of coal,, .Screening is one of the most basic techniques used in coal preparation,, .

Coal Vertical Mill. Ore Vertical Mill. Raw Vertical Mill. Slag Vertical Mill. Slag Ball Mill. Rod Mill. Cone Ball Mill. Vertical Roller Mill. Dust Collecting Equipment MORE > ... Trommel Screen. YK Vibrating Screen. Linear Vibrating Screen. YA Circular Vibrating Screen. Crushing Equipment MORE > Jaw Crusher. Ring Hammer Crusher. Impact Crusher.

The Vertical Screen family of companies has built its reputation as one of the nation's leading providers of applicant screening services through well thought-out implementations, flawless execution and focused customer service and education. OUR HISTORY.

The Vertical Ore Launcher is a Contraband-tier utility item added in the Reincarnation Update, first sold nearly a month later on the 1st of May. The Vertical Ore Launcher, as its name implies, launches ore in a straight vertical manner. However, rather than launching conventionally, it uses anti-gravity to achieve this. For ores to be released from anti-gravity, a Gravity Normalizer must be used.

Vertical Screen Scroll Horizontal Vibratory Centrifuge Horizontal Scroll Centrifuge Vertical Vibratory Centrifuge Rotary Breaker Profile Wire Screens Polyurethane Screens Modular Panel Screens Tabor Pinless System Curved Static Sieve. Decanter Centrifuges Shale Shakers Dewatering Systems

Gone are the days when filming vertical videos was an unforgivable faux pas. Vertical videos (a.k.a portrait mode videos or upright videos) have now proven their worth and infiltrated every social media platform. So don't flip your phone, embrace being vertical with portrait videos. Download from our awesome range of over 300 free vertical ...

VM coarse coal centrifuges are flexible in operation and can be adjusted to be ideal for coal of a variety size ranges, including: § nominally less than 50mm and greater than 0.5mm in size. § nominally less than 12mm and greater than 0.5mm in size. The feed can come from a variety sources, such as dense-medium cyclone product screens.

Coal Screen Scroll Centrifuge GNCD930 Vertical Screen Scroll Centrifuge allows you to handle coal from higher fines recovery and maintaining the lowest product discharge moistures possible. The GNCD930 Coal Screen Scroll Centrifuge is designed for fine coal drying with significantly high capacity per .

Coal vertical mills are designed to achieve the maximum rated capacity grinding a design coal with a grindability of 55 HGI and 8-12 percent moisture and achieving a discharge fineness of 70 per cent passing a 200 mesh screen (74 micron) and 99.5 per cent passing a 50 mesh screen. Variation of the coal hardness and/or moisture content will ...

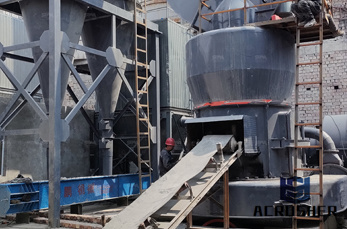

Great wall Machinery's Vertical Coal Mill technology reaches the international advanced level, and its manufacturing quality reaches the leading domestic level, and is the preferred equipment for grinding raw coal and soft coal. Process flow. 1. Raw coal from the yard are conveyed through screen .

L-N. Lignite A brownish-black woody-structured coal, lower in fixed carbon and higher in volatile matter and oxygen than either anthracite or bituminous coal. Heat content ranges up to 8,300 BTU/pound. (c) Load-Out Facility The basic purpose of a load-out facility is to get coal into rail cars, barges or trucks for movement to the destination. Important elements of such a facility include some ...

Jan 16, 2018· Roller Screen Roller Screens are suitable for separating fine, coarse and sticky coal. They are used in coal handling plant for preliminary screening and relief to crusher as well to ensure a clog free flow of coal. Roller Screens Consist Of Following Parts

Vertical Screen is unlike any applicant screening firm in the world. We are a family of four companies, each providing specialized services for specific markets. Vertical Screen is the parent organization, providing a foundation and support to our companies that empowers them to bring the most creative and innovative solutions to you.

The coal gangue after the second stage crushing and screening is transported by the belt conveyor to the vertical impact crusher for further crushing and shaping,until the customer needs the product.If the finished coal gangue has requirements on the powder content, it can be sent to a sand washing machine for cleaning or processed by a coarse ...

YZS Vibrating Screen. Belt Conveyer. Grinder Series. LM Series Vertical Mill. MTW Series European Technology Trapezium Mill. ... Vertical coal mill is a type of vertical mill used for grinding coal and applied widely in coal milling industry and coal mining industry.

Coal Vertical Mill. Cement Shaft Kiln. Flotation Machine. Vertical Lime Kiln. Cement Ball Mill . Thickener. Cement Vertical Mill. Cement Rotary Kiln . Zinc Oxide Rotary Kiln. ... ZK Linear Vibrating Screen. UF Series Mechanical Vibration... Sludge Dryer. TH Series Bucket Elevator. Trommel Screen. Hydro Cyclone. Continuous Ball Mill.

When it comes to grinding raw coal, savings in specific energy consumption can be achieved with vertical roller mills. Specific energy consumption depends on the grindability of the raw coal and the coal meal fineness required. A dynamic separator that ensures high separation efficiency also helps to reduce specific energy use.

GN Vertical Screen Scroll Centrifuge is designed for solids ... Coal, as an important energy source, is widely used in the world. As an international brand coal washing centrifuge manufacturer, GN is committed to providing high-quality solid-liquid separation solutions for the wet coal preparation industry.

screen segments troughs coal Prior art date 1894-09-25 Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Expired - Lifetime Application number Publication date 1894-09-25 1894-09-25 Application granted ...

Vertical coal mills are designed to achieve the maximum rated capacity grinding a design coal with a grindability of 55 HGI and 8-12 percent moisture and achieving a discharge fineness of 70 per cent passing a 200 mesh screen (74 micron) and 99.5 per cent passing a 50 mesh screen. Variation of the coal hardness and/or moisture content will ...

GNCD930 Vertical Screen Scroll Centrifuge allows you to handle coal from higher fines recovery and maintaining the lowest product discharge moistures possible. The GNCD930 Coal Screen Scroll Centrifuge is designed for fine coal drying with significantly high capacity per energy unit. Working Principle of GN Coal Screen Scroll Centrifuge

GN Horizontal Screen Scroll Centrifuge for Fine Coal is ... Coal Dewatering Screen Bowl Decanter Centrifue ... GN Vertical Screen Scroll Centrifuge is designed for solids ... Conveying Equipment . Solids Vacuum Pump. GN Solids Vacuum Pump is called sludge vacuum pump. It is a ... Progressive Cavity Pump. GNG series Progressive cavity pump is ...

Vertical coal mills are used for grinding bituminous coal, anthracite and petcoke for the burning systems in clinker burning and power generation according to the type and quantity of additives. Note: Raw coal size 40~50mm, feed moisture ≤15%, final product moisture ≤1.0%, final product finenessR80μm=10%~12% (bituminous coal.

WhatsApp)

WhatsApp)