WhatsApp)

WhatsApp)

Aug 30, 2012· Material is directly conveyed to the silos (silos are the large storage tanks of cement) from the grinding mills. Further, it is packed to about 20-40 kg bags. Only a small percent of cement is packed in the bags only for those customers whom need is very small. The remaining cement is shipped in bulk quantities by mean of trucks, rails or ships.

With four main and four support rollers, the mill will be used for grinding clinker/slag and will have a throughput capacity of 400 t/h. This makes it the largest LOESCHE cement mill in the ...

Effect of grinding aids on closed circuit cement grinding As introduced before, grinding aids are sprayed in the mill, or added on the clinker, with dosages usually ranging from 100-200 g up to 2-3 kg per ton of cement. Once a grinding aid is added during cement manufacturing, the main effect is the reduction of separator reject: more

- A series of real examples are exposed and interpreted. We also prove the impossibility of automating calculations.

Optimization of Cement Grinding Operation in Ball Mills Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pre-grinders with...

Module 2 – Ball mills. This module will cover the technology of ball mills used for raw and finish grinding in the cement manufacturing process. * Mechanical description of the different types of mills. * Ball mill grinding equations and dimensioning. * Mill internals, media, liners and diaphragms. * Ventilation, cooling and drying. * Control ...

Lvssn provides various grinding equipment for cement production line, including: Grinding mill,Ball mill,Rod mill,Roller press,Veritcal mill,Pipe mill

Aug 14, 2019· In 2016, LOESCHE supplied the Tepezalá cement plant of customer CYCNA, which belongs to the Cooperativa La Cruz Azul, S.C.L. with a complete cement grinding plant with a LOESCHE mill of the type LM 46.2+2 CS, which was successfully commissioned in August 2018. The mill's operating results have been exceptional from the very beginning.

Feb 10, 2016· re VRM vs Ball Mill for Cement Grinding. ... Process control/process technology- ball is operation friendlt and simple in operation but VRM requires some PID or control technology. Plant/system auxiliaries- less auxillaries in ball mill and hydraulic circuit to be maintained for VRM .

into fine and coarse fractions. For grinding in the cement production process the fine fraction is the finished product and the coarse fraction is returned to the grinding mill for re-processing. The evolution of the technology of classifi-ers has seen a transition from the so-called vortex effect Getting more from the cement ball mill with the

The Pavilion8 Cement Grinding Application offers process and quality control independent of system configuration.Whether faced with a traditional ball mill circuit, roller press, vertical mill or combined layout, the Cement Grinding Application, based on multivariable model predictive control (MPC) technology, has

The nano mill Zeta ® RS is the next development of the worldwide known circulation mill system Zeta ® type LMZ. Its field of application starts where the other agitator bead mill system Zeta ® ends. The highly efficient centrifugal separation system enables the use of smallest grinding media from a diameter of 30 – 300 µm in reliable continuous operation.

The history of the development of the technology of raw material grinding defines the early history of cement technology. Other stages of cement manufacture used existing technology in the early days. Early hydraulic materials such as hydraulic limes, natural cements and Parker's Roman cement were all based on "natural" raw materials, burned ...

Mill Grinding Course PCA offers an opportunity to learn the latest technical training on raw grinding and finish milling circuits and evaluation of their efficiencies over this two-day course. Kiln Process Program

In this chapter an introduction of widely applied energy-efficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given. A case study performed on a typical energy-efficient Horomill® grinding ...

Apr 21, 2015· Gebr. Pfeiffer MVR Roller Mills In the cement industry, MVR roller mills are used for grinding cement raw material, cement clinker, granulated blast-furnace slag, and .

cement industry the ball mill was really an epoch-making breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of .

Cement manufacturing - brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media - normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds.

Jun 07, 2018· The OK mill has been FL's standard cement vertical roller mill (VRM) since 1993. In 2017, FL also introduced the OK raw mill for raw material grinding.

PRINCIPLE BETA-MILL The technical principle of the BETA-MILL is pressure grinding. By having defined feeding velocity, material height and width, a defined layer of material will be fed to the pressure transaction zone (grinding zone). Homogenity and ideal pre-airing assure the perfect utilitisation of the employed energy in the grinding process.

Jun 11, 2018· This discovery lead to the development of our patented mills for pulverization: the LOESCHE LM-CS series (cement / slag). With the M+S technology developed by LOESCHE, these mills separate the preparation and grinding stages of the process and established an entirely new grinding-roller concept.

Cement Process & Energy Saving October, 2006 The Energy Conservation Center, Japan Tro Kawase. Laos 2006.10 2 ... JCA means Japan Cement Technology Association 2: Estimated based on 1.40 Nm3/kg-cl in SP kiln ... Addition of Grinding Balls Watch raw mill SEC daily and add grinding .

mills for dry-grinding the above-mentioned grinding stock. Loesche has developed and built the largest and most efficient grinding plants for its customers. Loesche plants are specifically planned for the required process steps and equipped with the associated techno logy. This technology comprises: • Processing plants and material storage

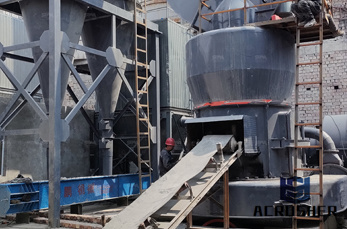

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

WhatsApp)

WhatsApp)