WhatsApp)

WhatsApp)

We are your first choice for the grinding of dry products! From A (activated carbon) to Z (zinc) - we offer the right mill for your product. Our extensive experience and wide range of mills are available for the fine cutting, fine grinding and ultra-fine grinding of dry products of all desired finenesses.

Home / Grinding Products ...

Grinding solutions – custom-tailored and effective for industrial minerals, ores, raw materials for ceramics, glass, fertilizers. EIRICH offers a range of mills and supplementary units for the very fine grinding of soft to very hard materials. They are also used for wet and dry grinding of very hard and highly abrasive materials.

Milling and grinding of raw material, minerals and cement is a rough process, with highly abrasive and hard feed materials that can accelerate equipment wear and tear. This leads to increased costs for equipment and spare parts replacement, and costly maintenance.

Grinding Products Nunc iaculis nisi suscipit euismod semper. Donec placerat ante sed erat commodo finibus vitae quis est. Nam vitae varius velit. > Learn More > Learn More

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill & ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

iron ball grinding mill manufacturer/supplier, China iron ball grinding mill manufacturer & factory list, find qualified Chinese iron ball grinding mill manufacturers, suppliers, factories, exporters & wholesalers quickly on Made-in-China., page 6

Grinding machine for making ballast grinding mill china. hsm grinding machine ball mill for granite. Grinding Mills: Ball Mill and Rod Mill Design and Parts 911 Metallurgist Common types of grinding mills include Ball Mills and Rod Mills. to highly abrasive materials, such as minerals, ores, stone, and chemicals., .. the entire mill is stressrelieved as a unit, prior to machining the ballast

Pet coke in cement clinker - SlideShare. Jul 11, 2015 ... GRINDING * Pet-coke being highly abrasive and hard, is difficult to grind ... content in pet-coke, it is difficult Use in Kiln * If the plants have single...

A comparison of wear rates of ball mill grinding media.pdf Journal of Mining and Metallurgy, 52 A (1) (2016 ) 1 - 10 # Corresponding author : alex.jankovic@

A grinding wheel is an expendable wheel used for various grinding and abrasive machining operations. It is generally made from a matrix of coarse abrasive particles pressed and bonded together to form a solid, circular shape, various profiles and cross sections .

As well as an extensive variety of abrasives for rough and precision grinding, finishing and polishing, Norton offers new innovations, on-site technical support and bespoke solutions for the engineering challenges faced in the industry. As the leader in abrasive technology, Norton provides added value abrasive solutions.

Baojie Abrasive Resistant Material Co.,Ltd established in 1995,located in the grinding media ball hometown,our casting grinding ball, forged grinding ball, and grinding cylpebs are widely used in ball mills of cement plant, power station,chemical industry and gold & Iron mining industry.

Amazon : Powerful Electric Grain Mill Grinder for Home and ... HIGHLY CERTIFIED; LIFETIME WARRANTY - Wondermill flour grinder mill complies with the most ..... NutriMill Harvest Stone Grain Mill, 450 Watt - Black. ... clasifiion ofmine plant design and grinding ball mill machines.

The Preliminator mill is a type of ball mill used for coarse grinding in open circuit or for fine grinding in closed circuit. Preliminator mills are widely used in the cement industry for the reduction of cement raw materials and clinker. It is also used for the reduction of abrasives, refractories, limestone for .

Grinding Media Balls and Cylpebs Prominent & Leading Manufacturer from Jaipur, we offer grinding balls, grinding media balls, hyper steel grinding media ball ( as per is 6079), grinding media, grinding media balls for africa and high chrome grinding media balls.

plant fit with this requirement: from coarse to very fine product, from dry to highly moist material, and from soft to very abrasive compound, the FCB Horomill is suitable for multiple applications. Raw meal grinding The conventional FCB Horomill grinding plant is composed of a mill operated in closed circuit with a third generation

Our ATOX® Coal Mill has large rollers with great grinding capability of virtually all types of raw coal. The rollers work harmoniously with a highly-efficient separator and feed sluice to consistently and reliably deliver coal meal to your desired fineness and moisture level.

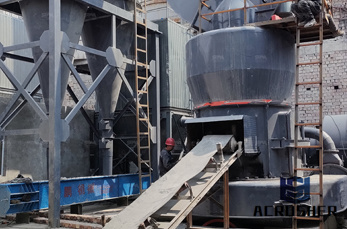

MTM trapezium mill is a new type of industrial mill designed on the basis of Raymond mill, creating a new mark post in the grinding mill industry. The MTM Medium Speed Trapezium Mill is the world's leading industrial mill. Feed particle size: 0-35mm Production capacity: 3-22 tons / hour

During mill operation, grinding balls wear and are reduced in size. In doing so, the grinding characteristics change. The extent of wear would depend on the characteristics of the rock present, such as surface hardness, density and composition. The abrasive action .

Calcium carbonate (CaCO 3), which occurs primarily in the form of the minerals calcite and aragonite, is one of the most prevalent compounds on Earth.Calcium carbonate is not only the main component of marble, limestone and dolomite, it is also found in bones and teeth as well as the exoskeleton of crustaceans, coral, muscles, snails and protozoa.

grinding system One of the principal reasons for the outstanding success of the high-pressure grinding roll in the cement industry is its low power requirement. Today, this mill is employed all around the world for the grinding of cement raw material, cement clinker and granulated blast furnace slag. For new plants, the POLYCOM ® is an eco-

mill commonly found. Grinding mills Ball mills Ball mills vary in their details and size but the basic design consists of a horizontal hollow cylinder, with an abrasion-resistant interior, that rotates about its central axis. The grinding is performed by stone, metal or rubber balls that are free to move in the cylinder (Figure 1).

high aluminum grinding mill manufacturer/supplier, China high aluminum grinding mill manufacturer & factory list, find qualified Chinese high aluminum grinding mill manufacturers, suppliers, factories, exporters & wholesalers quickly on Made-in-China., page 4

WhatsApp)

WhatsApp)