WhatsApp)

WhatsApp)

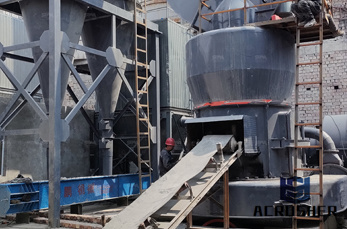

Bar Rolling Mill Annual Capacity: 30,0000 ∼ 50,0000 TPY. The billet is 150mm *150mm *8000mm continuous casting billet with a billet weight of 1404 kg. Products: hot rolled round steel, ribbed steel bar. Rolling Speed: maximum finishing speed of 16 m/s. Specification: round steel ∅14mm~∅40mm, ribbed steel ∅12mm~∅40mm.

The Eaton Steel Bar Company catalog by no means contains all the items we stock. However, it does provide a list of the commonly stocked items we inventory every day. Based on customer demand and feedback, our stock position items are adjusted as needed. Take a look at our catalog and see the breadth of what we provide.

Nov 29, 2016· Built in 2000, the Hertford County mill produces 1.6 million tons of carbon, alloy and high strength, low alloy steel plates including quenched and tempered and normalized steel plates. The plate mill produces plate for many products, including armored .

China Cold Rolling Mill manufacturer, Milling . 650-1780 6hi Reversible Cold Rolling Mill Production Line/ Plain Carbon Steel Steel Rolling Mill/ Steel Plant Rolling Mill FOB Price: US $1,000,000-5,300,000 / Piece Min. Order: 1 Piece

cold rolled stainless steel plant from hr to cr; hot dip galvanizing plant; forging on open die hammers; steel rolling mill; steel fabrication unit; good future prospects for tmt bars; butt welded carbon steel fitting and steel flanges; reinforcement steel bar tor bar; iron ore pelletization; fastener (automatic cold forge process) ss sheet ...

Hagerty combines a large inventory of carbon, stainless, alloy & tool steels, aluminum, brass & copper with great processing capabilities. This ISO 9001:2000 certified metals service center works hard to exceed your expectations for plates, sheets, structurals, tubing, pipe, hot rolled & cold finished bars, coil processing, expanded metal, drill rod & more!

This makes cold rolling a more labor intensive and expensive process than hot rolling. Cold rolling can also reduce the grain size of the metal resulting in Hall-Petch Hardening. Both hot rolling and cold rolling are used to create sheet metal. However, cold rolling produces thinner sheets.

Technology and equipment for Cold Rolling Mills Tenova I2S is a recognized leader in technologies and innovative design and supply of cold rolling mills. Since 1974, Tenova I2S has specialized in providing customers the highest quality solutions in a broad range of mill types for production of stainless steel, carbon steel, specialty steels and ...

Apr 06, 2020· The new plant will provide improved tolerance and mechanical properties for high-quality carbon steel products. The mill will include a high-speed rod outlet with 250 "V" pre-finishing mill, 680 shear, eight-stand 250/230 Morgan Vee No-Twist Mill, 250/150 RSM, Pinch Roll/Laying Head, an 11-zone Morgan Stelmor Conveyor and a stepless reform ...

Projects on Steel and Steel Products, Rolling Mill, Foundry, Mild Steels, Iron and Steel, Ferrous Metals Products, Alloy Steel, Cold Rolling, Hot Rolling, Pelletizing, Stainless Steel, Steel Mill, Carbon Steel, Forge Products etc

As one of the largest processors and distributors of flat rolled carbon steel in North America, we're pleased to be able to offer our customers an extensive inventory of grades and sizes. ... Cold Rolled Carbon Steel Electrogalv Carbon Steel ... Tin Mill Products Aluminized Carbon Steel. Specification. ASTM. Grade HIGH STRENGTH LOW ALLOY ...

Carbon Steel Products: Beams "I" beams, Junior beams, Wide flange beams in ASTM A-36, ASTM A-572M, ASTM A-709M, A-992M specs. Channels. Bar size channels, Ship & Car channels and Structural channels in ASTM A-36, ASTM A-529 Gr50, ASTM A-572 Gr50, SA36 & ASTM A-709 Gr36 specs

While 95 percent of ArcelorMittal's raw steel production in the United States is from flat carbon operations, we also produce long carbon steels, tubular products and tailored blanks. All of our products are available in standard carbon grades as well as the latest innovative advanced high-strength grades for more demanding applications.

This cold rolling mill machine consists of main unit, main motor, reducer, herringbone gear one machine, universal joint shaft, electric screw down gear and electric control etc..The cold rolling mill is applied to carbon steel, special steel, and another strip rolling. Particularly suitable for rolling high-precision flat, thin strip.

Cold Rolled (CR) steel is manufactured from hot rolled coils by pickling to remove the surface oxide produced during the hot rolling stage, and cold reducing through a cold mill to the desired thickness. Cold reducing steel produces a low ductility product that is usually processed further to develop desired end use characteristics.

With the advancement of technology in rolling mills, the size of rolling mills grew rapidly along with the size of the products being rolled. One example of this was at The Great Exhibition in 1851, where a plate 20 feet long, 3 ½ feet wide, and 7/16 of inch thick, and weighing 1,125 pounds, was exhibited by the Consett Iron Company. [8]

Cold Rolling Mill. AGC Hydraulic 6 Hi Cold Rolling Mill 700mm Carbon Steel 390m / min Speed. Automatic Cold Reversible Rolling Mill 4 Hi 650mm AGC Screw Down Type. Rigid 20 High Cold Rolling Mill Machinery, High Precision Stainless Steel Rolling Mill. Temper Rolling Mill. Hardened Temper Rolling Mill Four Roller For Carbon Steel High Elasticity

Cold Rolling of Mild Steel Strips & Sheets-0.00: 0.00: Cold Rolling of MS Strips-0.00: 0.00: Cold Rolling of Steel Strips-0.00: 25.91: Cold Rolled Forming of Sections for Purling & other Section for Industrial Handling of Rolling Mill-0.00: 0.00: Cutting and Finishing of Metal (Aluminium and Stainless Steel)-0.00: 0.00: Cold Rolled Steel Strips ...

Steel - Steel - Forming of steel: Forming processes convert solidified steel into products useful for the fabricating and construction industries. The objectives are to obtain a desired shape, to improve cast steel's physical properties (which are not suitable for most applications), and to produce a surface suitable for a specific use.

Cold rolling technology for carbon Author: Claudia Stingl Subject: Cold rolling technology for carbon steel strip Keywords "Cold rolling, rolling technology, rolling mill maintenance, rolling mill modernization" Created Date: 12/2/2014 12:53:33 PM

Our capabilities range from formable low-carbon grades to ultra-high-strength steels. Cold-roll steel sheet. After hot-rolled sheet is pickled, leveled, and edge-trimmed, our cold-rolling mill is capable of reducing the steel's thickness to as thin as 0.013 inches and as thick as .085 inches. Coated steel sheet

Cold Rolling Mills Tenova I2S is a recognized leader in technologies and innovative design and supply of cold rolling mills. Since 1974, Tenova I2S has specialized in providing customers the highest quality solutions in a broad range of mill types for production of stainless steel, carbon steel, specialty steels and non-ferrous metals.

Hot-rolling mill: Equipment on which solidified steel preheated to a high temperature is continuously rolled between two rotating cylinders. Cold rolling mill: Equipment that reduces the thickness of flat steel products by rolling the metal between alloy steel cylinders at room temperature.

With the advancement of technology in rolling mills, the size of rolling mills grew rapidly along with the size of the products being rolled. One example of this was at The Great Exhibition in 1851, where a plate 20 feet long, 3 ½ feet wide, and 7/16 of an inch thick, and weighing 1,125 pounds, was exhibited by the Consett Iron Company. [8]

WhatsApp)

WhatsApp)