WhatsApp)

WhatsApp)

During the travel of the grain from farm to fork, it passes through many steps and processes. After harvesting, cleaning can be said as the first step of those processes which the grains are separated from the impurities and residues like stones, husks, straw, soil, dust, seeds etc. Mechanical separation methods of vibration, aspiration, size grading and magnetic separation are generally used ...

After graduating from Swiss Milling School in 2010, joined Oman flour mills, Muscat as Flour Mill Manager, responsible for complete operations of flour mill activities. In 2016 joined /African Milling School in Kenya as a Milling techncologist and Techincal teacher, performing plant commisioning/start-ups and mill auditing.

53 Flour Mill Maintenance jobs available on Indeed. Apply to Packer, Maintenance Person, ... Responsibility for overall maintenance of the Flour Mill, Elevator, ... Sized moving mechanical parts, flour dust and/or airborne particles.

The Basic Milling Procedures course covers the setup and use of the horizontal milling machine, and describes the functions of basic cutters and attachments. Uses "hands-on" projects so trainees actually gain experience on the milling machine. Includes a work-holding fixture project that can have practical value in the shop when finished. TPC Training is authorized by IACET to offer 0.5 CEUs ...

Apply to 56 Flour Mill Jobs on Naukri, India's Job Portal. Explore Flour Mill Openings in your desired locations Now!

The advanced level for Head Millers is a combination of lectures and hands-on training in a professional manner. The state of the art school mill allows practical training on wheat and maize milling. There is a fully equipped laboratory that will allow the participants to learn all about quality control from grain to flour.

Navajo Pride Flour Mill LLC – 245 Road 4063 Farmington NM 87499 ... Performed minor mechanical work and routine equipment maintenance. ... International Grains Program Short Milling Course Certificate. HACCP Certificate. Build Your Own Now. Resume Overview. Companies Worked For:

successfully completed a course on Flour milling Technology Mechanical and Electrical Maintenance fromjun 7th _july 3rd 1993 covering the following subjects:cleaning House Mill Finished Products Handing section as interpreter Uzwil(Switzerland),3rd july 1993

MINNEAPOLIS, MINNESOTA, U.S. — The Grain Elevator and Processing Society (GEAPS) and Kansas State University (KSU) are offering online courses focusing on inspections, quality management systems, maintenance, safety and flour milling. The five courses will run from Oct. 29 through Dec. 3, and registration closes Oct. 23. The GEAPS 522: FGIS Grain Inspection Orientation was developed .

From Engineering to Milling. ... This was a link between an agriculture commodity and the end user consuming bread and flour-related products. ... organization comprised of grain millers and allied trades representatives devoted to the advancement of education and training opportunities in the grain milling industries. Visit IAOM.

You can use the latest online support system or telephone to obtain professional advice, with our service team and decide whether you need technical assistance on site. Maintenance. Even the most solid and reliable machine equipment need regular maintenance. We can offer all the products according to your need reliable maintenance services. Inquiry

IAOM tackles today's most relevant issues, gathered from sources like The Associated Press, The New York Times, Financial Times and the leading industry publications.Each week features a different topic geared toward the operative miller: HR, employee and environmental safety, operations and facility management, and industry news.

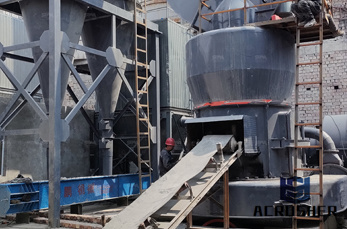

Flour Milling System 100-1000tons/day of wheat flour milling plant. Full automatic pneumatic flour mill, plansifter, purifier, flour checking and flour packing system. With low prerssure dust removing system, it will make clean workshop. 100-1000tons per day of wheat flour mills Wheat storage with steel silos and bulk wheat receiving system.

The diverse list of courses cover various fields of activities such as traditional flour milling, maize milling, oat processing, a combination of flour milling and baking, mechanical and electrical maintenance as well as plant automation. The courses are constantly updated with the latest technology available on the market.

About. Experienced Supervisor with a demonstrated history of working in the manufacturing industry. Skilled in Mechanical engineering, Technical Flour Milling, Manufacturing,plant Maintenance, Continuous Improvement, and Supervisory.

Apr 18, 2009· Design Considerations for the Construction and Operation of Flour Milling Facilities. Part I Planning, Structural, and Life Safety Gregory D Williams, Ph.D., . Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising.

GEAPS 630: Quality Control, Quality Assurance Practices in Flour Milling. 2020 course offerings. Oct. 27-Dec. 8 – Register online or download a registration form.Registration closes Oct. 21. Course Description: This course focuses on the quality control and quality assurance principles of milling, including milling process quality, flour analysis, sampling and additives.

Mechanical Maintenance Online Course For Flour Milling. mechanical maintenance online course for flour milling mechanical maintenance online course for flour milling Computer Bit Slices of a Life Columbia University in He would be 74 next month although no .

Mechanical Maintenance Online Course For Flour Milling. OCRIM Milling Technology School is considered as one of the company's the profession of responsible in charge of mechanical maintenance in a flour mill. Get Price Industrial Maintenance Training Online . Flour Mill Maintenance Crusher Mills, Cone Crusher, Jaw. Flour Mill Maintenance ...

It applies to flour milling operations for all types of grain including wheat, oats, barley, corn, rice, sorghum, millet, rye, and non-grain flours such as peas and arrowroot. Units selected from other Training Packages must be relevant to the work outcome, local industry requirements and the Qualification level.

Milling Technician Program Overview. This unique certificate program prepares candidates to work in flour mills as an associate working in many of the areas of the modern mills. Studies will include basic math needed for the mill environment, as well as an overview of equipment, electronics and electricity, and pneumatic fundamentals.

Oct 23, 2019· The Grain Elevator and Processing Society (GEAPS) and Kansas State University offer five courses online courses in October. Courses run from Oct. 29 through Dec. 3, and registration closes Oct. 23. GEAPS 522: FGIS Grain Inspection Orientation This course was developed by the USDA's Federal Grai

IAOM Correspondence Course in Flour Milling. Developed and reviewed by industry experts, the IAOM Correspondence Course in Flour Milling is comprised of eight units encompassing all aspects of flour milling from wheat cleaning, basic milling principles, storage and grain handling to milled-grain product additives, plant management and mill mechanics.

establishing priorities in maintenance schedules. • Maintains manufacturing assets and facility, parts inventory, monitoring purchase orders, invoice approvals, and manages the department budget. • Manages maintenance personnel by setting direction and priorities. • Provides training and continuous development on all maintenance personnel.

WhatsApp)

WhatsApp)